Our predecessor, Ogura Oil Mills (founded name: Yamamasu Hydrogenated Oil Factory), had been hydrogenating fish oil (squeezed sardine oil) and accompanying soaps, fatty acids, and glycerin since the 1920s (late Taisho era). However, in the midst of the fierce battlefield of World War II, it was decided to be integrated into Nikka Oil Mills (currently J-Oil Mills) due to corporate development through oil and fat control.

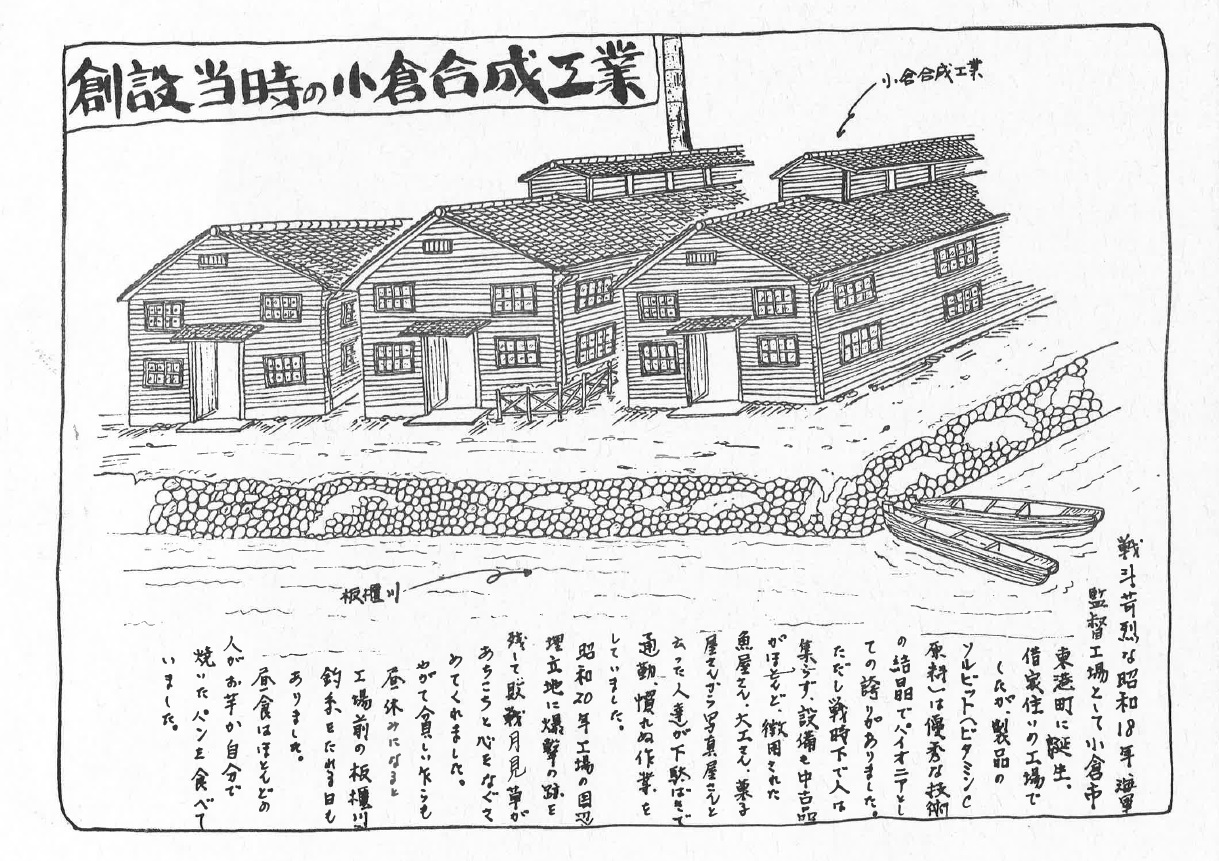

At that time, vitamin C was needed as a fatigue recovery agent for warriors, but the raw material, sorbitol, relied on 100% imports, and it was not available during the war. At that time, we were creating a sorbitol manufacturing method with a purity that surpassed that of Western products, and in response to a strong manufacturing request from the military, we decided to newly establish a naval supervised factory in Kokura City (currently Kitakyushu City) in Higashi Port Town.

After that, at the end of the war, while overcoming a series of hardships such as factory relocation and factory damage, when the oil and fat control was lifted, we advanced with the oil and fat processing technology inherited from the predecessor company thus entered the field of oil and fat chemistry publicly.

Established Kokura Gosei Co., Ltd.

- Established capital: 180,000 yen) at 6-2, Higashiminato-cho, Kokura-shi for

- Manufacturing and selling Solbit and its derivatives (30tons/month), designated as a Navy supervised factory.

- Raised capital to 1 million yen

- Moved factory to 7-2, Higashiminato-cho, Ogura City,

- newly established a sorbit factory, a saccharification factory, and a hydrogenation facility.

March 1950

- Factory fire burns down sorbitol factory, saccharification factory, and warehouse

工場火災により、ソルビット工場、糖化工場、倉庫を焼失

After the oil and fat control lifted, we focused on oil and fat processing business, since then we have been engaged in high-pressure decomposition of fatty acids, production of hydrogenated oil (wax), and production of glycerin. By decomposition of "castor oil", we succeeded in mass production of sebacic acid, which is a raw material for plastics, and became the starting point of our prosperity.

Since then, we have repeatedly expanded and boasted the largest production volume in Japan (maximum annual production of 2,000 tons), and thus have grown significantly in harmony with Japan's high economic growth.

- Following the lifting of oil and fat control, oil and fat decomposition and fatty acid distillation equipment were newly installed and oil and fat processing was commercialized.

- Started production of sebacic acid

- Initial production capacity of sebacic acid 100 tons per year

- Repeated expansion five times from 1962 to 1969.

1958 Firefighting Training

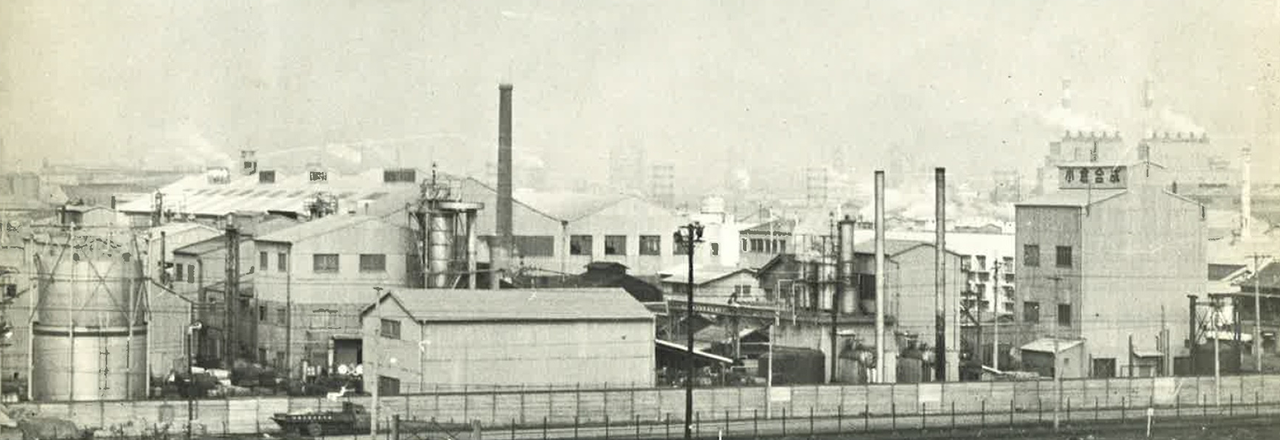

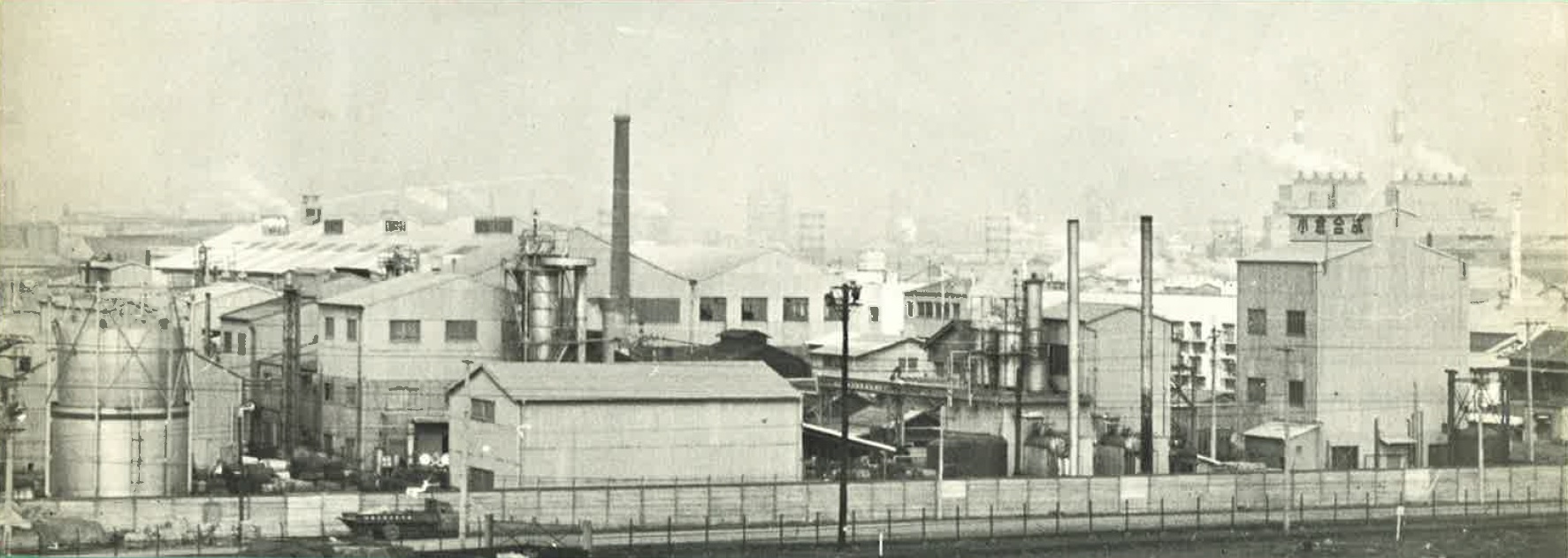

1960 Overview of production facilities

- Opened Osaka Sales Office

- Established 500 kl of castor oil tank yard in Nishiminatomachi, Kokura-ku, Kitakyushu (currently Kokurakita-ku, Kitakyushu)

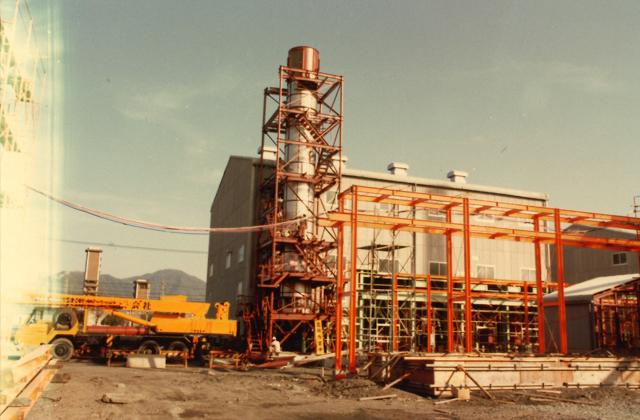

In 1975, due to construction of urban expressway, our factory relocated. The new factory was completed in 1980 and moved to its current location (1-4-8 Higashiminato, Kokurakita-ku, Kitakyushu City) and started operations. As it was a remarkable turn point while also seeking factory developing approval for a bonded factory and also for the purpose of increasing exports, we reform our business as a company, and we utilize our proprietary technologies of high-pressure reaction, hydrogenation, and distillation refining to carry out contract manufacturing from customers. The high demand for our unique technology helped us grow (Fine chemical business unit), which is one of our main businesses even today. By increasing number of contracted projects, we adopted to expand gradually to cope up with customer requests.

- Increased capital to 10 million yen

1976 Skyview (middle area is Kokura Gosei’s premises)

- Headquarters / factory relocated to current address, new test and research building established

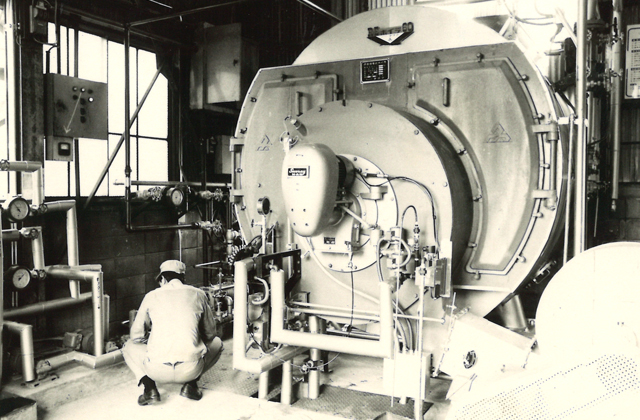

1980 Boiler installation

1980 R&D building (construction)

980 New plant construction

- Precision distillation equipment newly installed

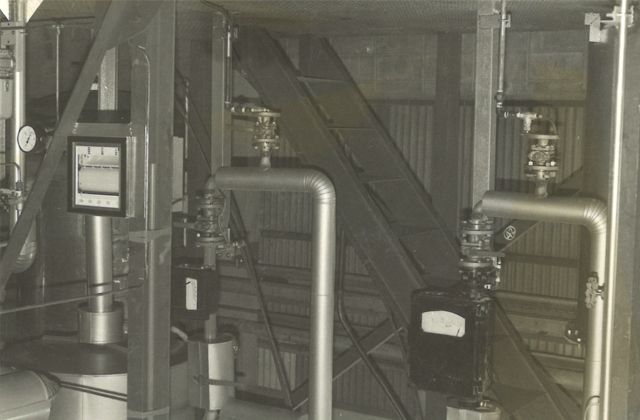

1981 Hydrogeneration unit

1981 fractionation unit

- Obtained a bonded warehouse / bonded factory permit

- New pilot plant established

- Added infrastructure i.e., 1,000kl tank to castor oil tank yard

1995 west bay yard

- Obtained ISO9001 certification

- Increased capital to 50 million yen

Since 1990, many disasters such as the Heisei Great Recession after the burst of the bubble economy, the Lehman shock, and the spread of the coronavirus have hit us, and the business environment will continue to be extremely difficult. However, we have overcome many great difficulties from the turmoil of WW2 to this day. It is the result of inheriting the identity of natural fats and oils from the time of its founding, which was based on many technologies and ingenuity, experience and ability to withstand difficulties, and will continue to enrich people's lives while protecting the global environment. We will continue to innovate and create new value not only in Japan but also in the world toward a new future.

- 70th anniversary of foundation

- New precision distillation facility added

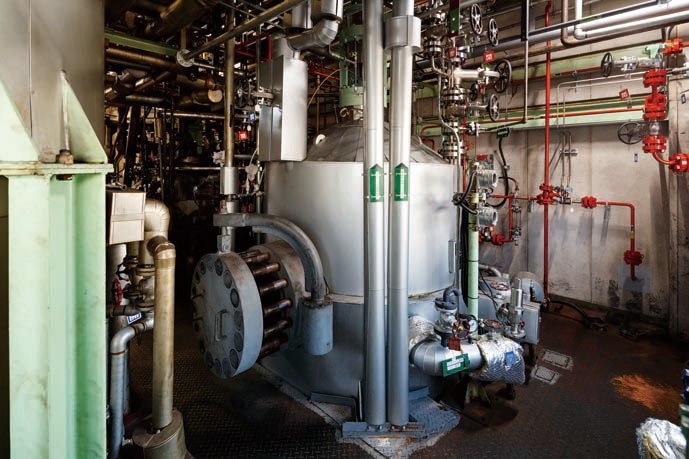

- New high-pressure hydrogenation equipment facility added

High pressure hydrogeneration unit

- Osaka sales office relocated

Inquiries related to product Catalogue and SDS, consultation on products and contract manufacturing and any other inquiries please contact us by phone or using the inquiry form.