Contracted manufacturing

Helping customers to shape their requests with our technology

概要

Taking advantage of the knowledge and know-how that we have accumulated over many years, we are able to provide one-stop support for development research, various laboratory prototypes, and actual machine production, and we support the realization and commercialization of various needs from many users within our domain.

We also carry out research contract aimed at establishing contracted production and economical industrialization processes that utilize R & D capabilities and manufacturing technology. We also strictly adhere to the management of confidential information, and we strictly manage not only the information disclosed by our customers but also the information obtained during the implementation at our workplace.

Our specialized processes

- High pressure contact reduction

- Hydrogen decomposition

- Saponification decomposition

- Dehydrogenation reaction

- Alkaline melt oxidation

- Garbet reaction

- Oxolation (hydroformylation)

- Amination

- Nitrilation

- Esterification (dehydration condensation)

- Transesterification

- Aldol condensation

- Acetylation

- Diels-Alder reaction

- Diazotization

- Hydride reduction

- Michael reaction

- Distillation purification

- Centrifugal separation

- Drying and crushing

production equipment

- Hydrogenation equipment (low pressure / high pressure)

- Capacity: ~ 5.5m3 Pressure: ~ 10MPa Temperature: ~ 270 ℃

Ammonia and carbon monoxide gas can be used

- Reaction equipment

- Capacity: ~ 15m3 Pressure: Normal pressure Temperature: ~ 320 ℃ Brine can be used (partial)

- Distillation equipment

- Capacity: ~ 6.0m3 Pressure: 5To ~ Normal pressure Temperature: ~ 300 ℃

- Other equipment

- Filtration equipment, centrifuge, granulation equipment, flaker, crusher, conical dryer, etc.

- Analysis equipment

- GC, GC-MS, LC, UV, FT-nIR, TG-DSC, viscometer, refractive index meter, Karl Fischer titer, pH meter, etc.

- utility

- 3 steam boilers, 2 heat medium boilers

Three-dimensional automated warehouse wastewater treatment equipment (activated sludge method / coagulation sedimentation method)

Deodorizer facilities

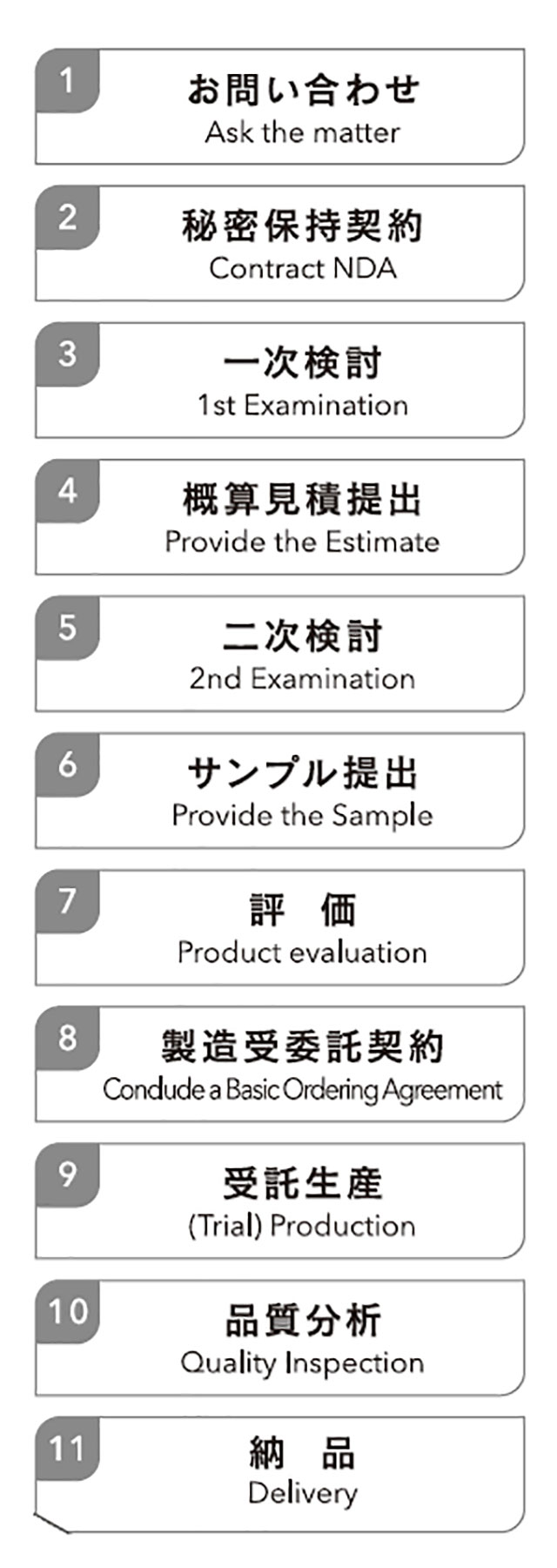

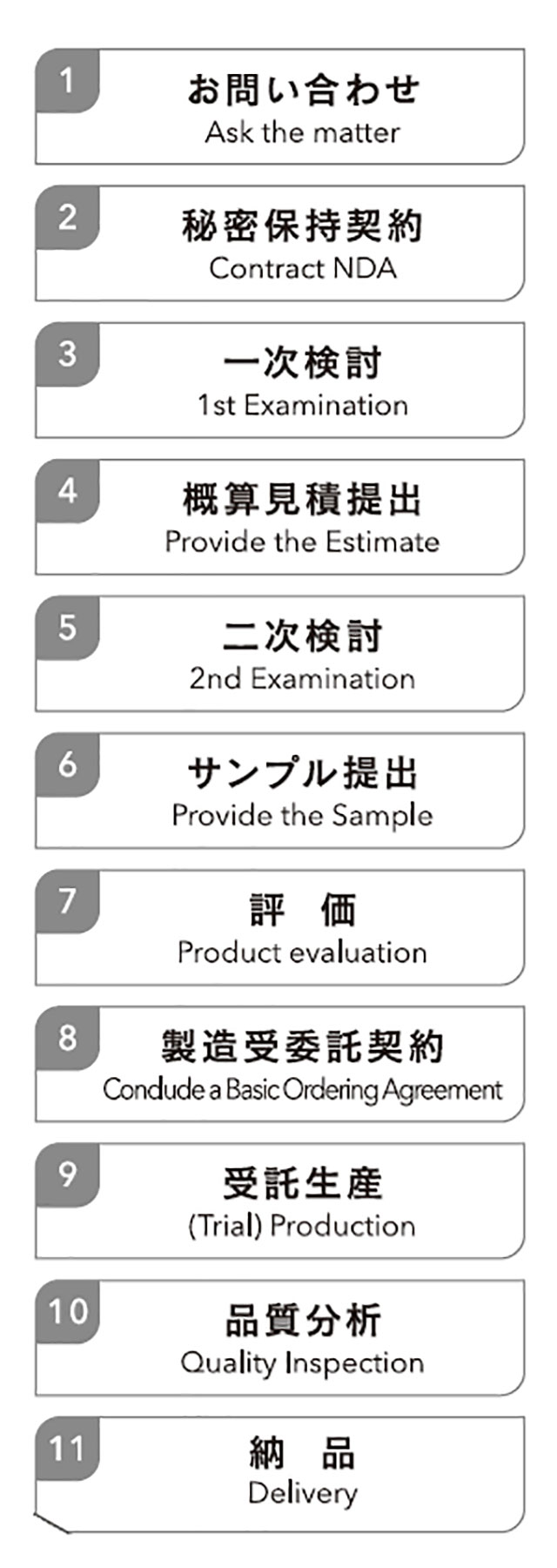

Flow of contract production

From inquiries to delivery * Refer to the old company pamphlet